The oil bunkering industry, a critical component of global maritime trade, faces increasing pressure to operate efficiently, sustainably, and in compliance with stringent environmental regulations. From managing fuel quality to mitigating spills and ensuring operational safety, the challenges are multifaceted. CleanGo Innovations’ CG-100 product offers a revolutionary solution designed to address these very pain points, bringing a host of benefits that can significantly enhance the profitability, environmental stewardship, and operational integrity of oil bunkering businesses.

Enhanced Fuel Quality and Efficiency

One of the primary concerns in oil bunkering is the consistent quality of the fuel delivered. Substandard fuel can lead to engine damage, reduced vessel performance, increased maintenance costs for clients, and even regulatory fines. CG-100, with its advanced formulation, directly impacts fuel quality in several key ways, ensuring that the bunkered fuel meets or exceeds operational standards:

Sludge and Sediment Reduction

Fuel often contains asphaltenes, paraffins, and other heavy hydrocarbons that can precipitate out and form sludge and sediment, particularly during storage or due to temperature fluctuations. CG-100 acts as a powerful dispersant, preventing these particles from agglomerating and settling. It keeps them suspended in the fuel, allowing them to be consumed during combustion. This significantly reduces filter clogging, minimizes wear on fuel pumps and injectors, and decreases the need for frequent tank cleaning, thereby reducing maintenance downtime for vessels and the bunkering infrastructure itself. This translates to more reliable fuel delivery and happier clients.

.

Improved Combustion

By promoting a more homogenous fuel mixture and reducing the presence of contaminants, CG-100 facilitates more complete and efficient combustion within marine engines. This is achieved by ensuring that fuel particles are finely dispersed and readily available for ignition. More complete combustion means less unburnt fuel, which directly translates to improved fuel efficiency for the end-user. For the bunkering company, this means offering a premium product that helps clients lower their operational costs, potentially leading to increased demand and stronger client relationships. Furthermore, better combustion can reduce carbon deposits in engines, extending their lifespan.

Water Emulsification

Water contamination, whether from condensation, leaks, or delivery processes, is a persistent and damaging issue in marine fuels. Free water can cause corrosion in fuel systems, promote microbial growth (fuel bug), and lead to engine instability or even shutdowns. CG-100 possesses unique emulsifying properties that allow it to encapsulate small amounts of water, dispersing them evenly throughout the fuel. This prevents the formation of damaging free water pockets and allows the water to pass harmlessly through the system and be consumed during combustion or removed by standard fuel-water separators without causing damage. This extends the life of critical fuel system components and engines, reducing costly repairs and operational disruptions.

Superior Environmental Compliance and Spill Response

The maritime industry operates under increasingly strict environmental regulations, such as those from the IMO (International Maritime Organization) and local authorities, which impose heavy penalties for non-compliance and environmental damage from oil spills. CG-100 provides both proactive and reactive solutions to these challenges, bolstering a bunkering company’s environmental credentials:

Effective Spill Remediation

In the unfortunate event of an oil spill, rapid and effective response is paramount to minimize ecological damage and financial liability. CG-100’s unique properties allow for the rapid dispersion and breakdown of hydrocarbons into smaller, more bioavailable molecules. Unlike traditional dispersants that merely spread the oil, CG-100 actively accelerates the natural biodegradation process by making the hydrocarbons more accessible to naturally occurring microbes. This significantly reduces the long-term environmental impact, mitigates the spread of the spill, and drastically cuts down on the extensive and often prohibitive costs associated with conventional mechanical clean-up methods, such as booming, skimming, and waste disposal. Its efficacy in various water conditions makes it a versatile tool for emergency response.

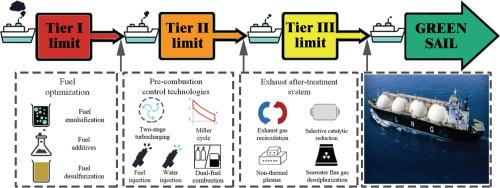

Reduced Environmental Footprint

While primarily a fuel treatment and spill response agent, CG-100 indirectly contributes to a broader reduction in the environmental footprint of maritime operations. By improving fuel combustion efficiency, it helps vessels reduce their consumption of fuel, which in turn leads to lower emissions of greenhouse gases (like CO2) and other harmful pollutants (like NOx and SOx). This aligns directly with global efforts to decarbonize shipping and improve air quality in port areas and along shipping lanes, allowing bunkering companies to support their clients in meeting stricter emission targets.

Non-Toxic and Biodegradable

A critical advantage of CG-100 over many conventional chemical dispersants is its formulation. It is designed to be non-toxic and readily biodegradable, meaning it breaks down naturally in the environment without leaving harmful residues. This characteristic is vital for protecting sensitive marine ecosystems and aquatic life during application, especially in ecologically vulnerable areas. Its non-toxic profile also simplifies handling and storage for bunkering personnel, reducing health and safety risks, and makes it more readily accepted by environmental regulatory bodies, facilitating quicker approval for use in emergency situations.

Operational Safety and Cost Savings

Beyond its direct impacts on fuel quality and environmental protection, CG-100 also offers tangible advantages that enhance operational safety and contribute significantly to overall cost efficiency for oil bunkering businesses:

Reduced Fire Risk

The accumulation of volatile organic compounds (VOCs) and flammable vapors in fuel tanks and enclosed spaces poses a significant fire and explosion risk, particularly during bunkering operations or in storage facilities. By effectively dispersing hydrocarbons and preventing the build-up of sludge and sediment, CG-100 helps to reduce the concentration of these volatile components. This contributes to a safer working environment for personnel, minimizes the potential for catastrophic incidents, and can lead to lower insurance premiums due to reduced risk profiles.

Lower Maintenance Costs

The benefits of CG-100 in maintaining cleaner fuel systems directly translate into substantial maintenance cost savings. By preventing sludge formation, reducing filter clogging, and mitigating corrosion caused by water, CG-100 extends the operational life of critical equipment such as fuel pumps, injectors, filters, and storage tanks. This leads to less frequent need for component replacement, reduced labor costs associated with cleaning and repairs, and fewer unexpected breakdowns. These savings apply both to the bunkering company’s own equipment used for storage and transfer, and indirectly to their clients’ vessels, further solidifying client loyalty.

Streamlined Operations

The ease of application and the multi-faceted effectiveness of CG-100 can significantly streamline various aspects of bunkering operations. By ensuring cleaner fuel, it reduces the need for extensive pre-treatment processes or on-board fuel conditioning for clients. In the event of a spill, its rapid action and biodegradability can simplify and accelerate clean-up efforts, reducing the time and resources required for incident management. This operational efficiency allows bunkering companies to optimize their schedules, improve turnaround times, and allocate resources more effectively.

Reputational Enhancement

In an increasingly competitive and scrutinized industry, a strong reputation for reliability, safety, and environmental responsibility is invaluable. Adopting an innovative, environmentally responsible product like CG-100 demonstrates a proactive commitment to best practices, sustainability, and client satisfaction. This enhances the bunkering company’s standing among clients (who value quality fuel and responsible partners), regulators (who appreciate efforts towards compliance), and the public (who are increasingly concerned about environmental impact). A positive reputation can attract new business, foster long-term partnerships, and provide a competitive edge in the market.

Conclusion

CleanGo Innovations CG-100 is more than just a chemical additive; it’s a strategic asset for any oil bunkering business looking to thrive in a demanding industry. By comprehensively addressing critical issues related to fuel quality, environmental protection, and operational efficiency, CG-100 empowers companies to deliver superior service, mitigate risks, ensure regulatory compliance, and ultimately, achieve greater profitability and long-term sustainability. Investing in CG-100 is an investment in the future of responsible, efficient, and resilient oil bunkering operations.